Fasteners are the components used to connect or join two or more objects. They help make a permanent or temporary, yet strong connection between two objects. As the years passed fasteners have been updated with the latest technological advancements. Fasteners used today are significantly different from those used several years back. The fastener technology has seen a lot of advancements and has many advantages. How have these advancements helped fastener manufacturers? This post will explain how the manufacturers have benefited by these fastener advancements.

Trends in Fastener Technology

There have been a lot of trends in the developing technology of fasteners. The following are the upcoming trends:

- Use of New Alloys for Fasteners – As far as future advancements are concerned; several experts are presently trying new alloys for making fasteners. These newer alloys help improve properties and performance of fasteners in severe environments. Also, the new variants produced from new alloys can be made superconducting or ultra-light without compromising strength.

- Miniature Fastener Types and Styles – This is considered to be one of the biggest trends as far as fastening technology advancement is concerned. Nowadays, designs are getting more and more compact and thus are requiring lesser space. This in turn reduces the area required to place and install hardware. These miniature fastener designs are of great help in a wide range of industries, varying from electronics to aerospace. In certain applications, thin or even ultra-thin metal sheets are involved, which require threads. In such situations, miniature clinch fasteners are of great help. These fasteners are a great choice if you are looking for a reusable, permanent and strong threaded solution.

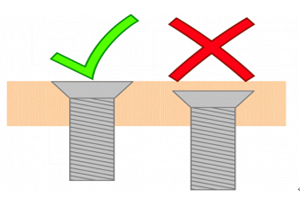

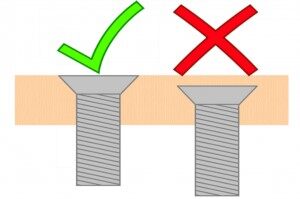

- Small Screw Insertion – A screw is used to hold two objects together firmly. If the screws are not fitted firmly and are left loose then it gives rise to several problems in an assembly. Manual installation of small screws into the conventional semi-automated power fastening tool is time-consuming. This hampers the productivity, thus increasing the associated costs. The conventional methods used for inserting screws are not capable of providing the seating torque. Thus, to overcome this problem, there have been several developments in the systems. These developments and advancements provide precise and quick small screw insertion.

- Installing Fasteners During Stamping Process – There has been one more advancement in fastening technology – the process of installing fasteners during the stamping process. This portable system works along with the stamping press to help feed, as well as install the fasteners. One of the major advantages of this system is that all the secondary operations for inserting fasteners are eliminated.

These are a few trends and upcoming advancements of fasteners. We can look forward to many more innovations in the fastener technology field in the years to come.